Atypical myopathy in horses is a severe and frequently lethal equine disease. Its cause is suspected to be the ingestion of a toxin and it develops sporadically. This illness causes a muscle disorder that progresses rapidly, with the characteristic of degeneration and necrosis of postural, respiratory and lingual muscles. The word “atypical” represents the fact that it […]

What is it? By filtering molecules over a gel, size exclusion chromatography (SEC) separates molecules according to their size (1). The gel is made up of sphere-shaped beads with pores that vary in size (1). When molecules of various sizes are passed through the gel, separation occurs because the smaller molecules can enter the pores […]

Incorrect Labelling If the labelling is done incorrectly and samples are mixed up as a result, the only thing we can do is repeat the whole experiment, wasting time and products. When using a handwritten label, make sure it is authentic; always add the date of labelling, the expiry date and your initials. […]

The identification, measurement, and purification of a specific analyte or chemical are the primary goals of the Chromatographic process. Examinations can be done both quantitatively and qualitatively. HPLC is just one aspect and can be used in the following applications (1): Purifying water Impurity detection in the pharmaceutical sectors Trace component pre-concentration Ligand-exchange Ion-exchange of […]

In order to quantify and identify the compounds separated in the column, HPLC analysis requires a detector to monitor the compounds themselves. The sort of detector used depends on what is being detected. It’s crucial to think about the type of sample you’ll be analysing before choosing a detector. On some detectors, certain sample types […]

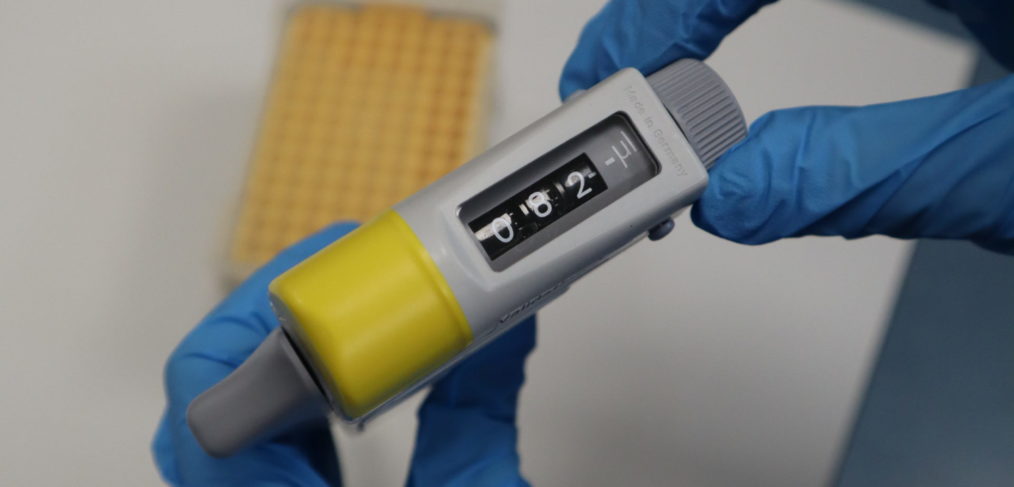

When it comes to pipetting, like with most scientific procedures, precision is essential. A minor error can have a significant impact on your results. In this post, we will share 8 tips that will help you improve your pipetting skills. Pre-wet the pipette tip Before aspirating for delivery, aspirate and totally expel a quantity of […]

High-performance liquid chromatography (HPLC) (Fig.1) is a chromatographic technique that is used to separate a mixture of substances in order to identify, measure, or purify the individual components of the mixture. How does HPLC work? The sample combination to be separated and evaluated is placed into a stream of mobile phase percolating through a column […]

Laboratory technicians are the “behind-the-scenes” professionals, who perform tests and experiments for research or diagnostic purposes. They help researchers and doctors reach conclusions and provide a better service/treatment for patients, respectively. To be a successful laboratory technician, certain skills are fundamental to get accurate and reliable results. Essential laboratory skills Attention to detail You must be […]

The most recent pandemic due to COVID-19 has certainly had a huge impact on our lives. One of the most affected sectors has been education. Face to face teaching had to be stopped and all teaching was given virtually. Thus, all lectures and practical classes were given online and students had to learn from home. […]

Our general lab skills course is designed to give you the basic skills needed to work in a GLP laboratory environment. You will receive in-house certification once the training is completed. To enroll on this course no previous experience is needed, however depending on your experience the training will be tailored to your needs. What […]